How Socks are Made

A brief synopsis of how socks are made:

|

Cotton is grown and harvested and sent to a yarn spinner. The Mayo family operates 2 farms in Eastern North Carolina where premium cotton is grown. |

|

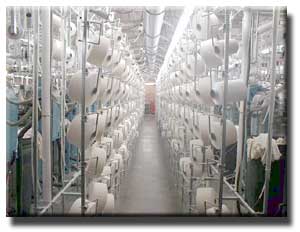

Yarn cones are purchased from the spinner. |

|

The cones are then loaded on to a yarn creel that supplies the knitting machine. |

|

The knitting machine has a cylinder that has 84 to 200 knitting needles surrounding it. The yarn is feed into the knitting machine and is knitted around the cylinder. The sock is knitted with the toe open. |

|

The toes in the sock are then sewed on automatic sewing machines. Once the toe is sewn the sock is called a "greige" sock. ("Greige" is pronounced like the color gray.) |

|

The socks are dyed in large dye machines. |

|

The socks then go to the "Boarding Department". The socks are slid onto metal foot that travels into a heated chamber. This gives the sock its final shape. You can think of the boarding machine as a large iron. |

|

The socks are individually inspected for defects and then are paired together. Labels and packaging are then put on the pairs of socks. |

|

Orders are filled by our Shipping Dept. |

Back to Top

|